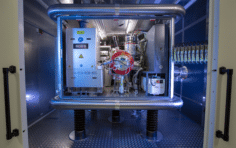

IBS is glad to announce that the contract to provide an additional High Current ion implanter upgraded with hydrogen implantation kit for H-cut applications has been signed with a worldwide leader in the manufacturing of SOI and POI substrates. This will be the 8th ion implanter of this configuration to be delivered by the IBS manufacturing center.

IBS is committed to Gender Equality and committed to provide career support to all employees as part of the standard procedures at IBS.

People have the freedom to choose and IBS creates a professional supportive environment to attract and support our employees. The Gender Equality Pay Index was created to measure and monitor this commitment.

The Index (max. of 100 points) is calculated each year using parameters dependent on the size of the company, pay scale, promotions, maternity leave, and top management population.

The Index score is made public and submitted to the labor authorities. If the result is below 75 points out of 100, the company must take measures to correct the situation within three years.

IBS is proud to announce the Gender Equality Pay Index score for 2020 obtained by IBS is 87/100

IBS decided 1 week prior the lockdown measures taken by the French government to replace the use of surgical masks with fabric masks for its clean room gownings. By doing this, IBS has been able to donate this week 750 surgical masks and 15 FFP2 masks as well as several hundreds of hairnets and overshoes to the Edmond Garcin hospital of Aubagne as a support to our local health workers fighting against the Covid-19 pandemic.

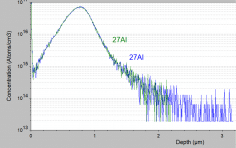

IBS confirms its position as an expert with the successful development of a specific and dedicated source to allow Al implantations up to 600KeV.

Such challenge offers new perspective to our clients, especially in the SiC applications, to implant their wafers for production volumes or R&d programs.

This capability is available for 4’’ and 6’’ wafers in automatic mode and can be combined with high temperature implant (up to 600°C).

IBS is glad to announce the delivery of its 7th fully refurbished and enhanced High Current ion implanter including several major upgrades for the manufacturing of Silicon-On-Insulator and Piezoelectric-On-Insulator substrates.

This delivery is the latest in a long-term operation consisting in providing major European and Chinese manufacturers with high-end equipment for the production of SOI/POI substrates. POI is the next generation engineered substrate for the realization of RF filters for 5G applications.

The PIN3S project covers Process Integration, creation of Lithography Equipment, EUV Mask Repair Equipment and Metrology tools capable to deal with 3D structures, defects analysis, overlay and feature size evaluation.

IBS partners with IMEC to develop new doping and material modification processes using the PULSION HP tool to improve the electrical performance and allow easier process integration of 3nm advanced devices (GAA and Nano-sheet based devices).

Project website

The HighLite project aims to improve the competitiveness of the EU PV manufacturing industry. by developing manufacturing solutions for high-performance low-cost modules with excellent environmental profiles.

IBS is in charge of developing new processes using its PULSION-Solar Plasma Immersion Ion Implantation tool for TOPCON, IBC and HJT solar cells as well as for cut cells used in advanced modules.

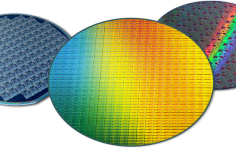

The 3rd and 4th FLEXion series ion implanters have been delivered to a major semiconductor manufacturer in Germany and to the Semi-Conductor Laboratory in India.

These production tools are fitted with the latest hardware and software enhancements to optimize ion implantation of III-V substrates. The III-V configuration is the second type of FLEXion series production ion implanters available in addition to the SiC high temperature/high energy configuration.

The National Nano Device Laboratories selected PULSION® Nano to pursue the development of their next generation green energy semiconductor devices.

By choosing PULSION® Nano, NDL will also reinforce their foundry offer to both academia partners and major memory and logic devices manufacturers for 3D structures – FinFET, ultra low energy doping and surface modification.

6” SiC high temperature implantation service is now available upon request. With this latest upgrade, IBS is now able to perform implants up to 600°C for both 4” and 6” substrates, with annealing up to 1 800°C.

Automatic chained implants are also possible thanks to the dedicated high temperature handling station fitted on our equipment.

The first FLEXion-400 ion implanter, latest evolution of the new IBS FLEXion line of products, has been delivered to a major research institute in China and is fully operational since May 2018.

The FLEXion line is the brand new generation of medium current ion implanters developed by IBS, and represents a leap forward in terms of productivity and performances compared to the IMC implanters.

The FLEXion implanters are available in both 200 kV and 400 kV acceleration voltage and are fitted with a high selectivity analyzer magnet and IHC ion source. They are optimized to address volume production for SiC and III-V substrates markets.

Following the initial certification of its core ion implantation foundry service in 2006, IBS has continuously expanded its Quality policy towards all its service & manufacturing activities. Today, IBS is proud to confirm the success of this commitment by achieving the certification of all its business units under the ISO 9001-2015 norm. This recognition strengthens the position of IBS among the major implanter manufacturers.

IBS is glad to announce the order of its first ion implanter IMC-200 in India. This system is configured to perform implantations in a wide range of temperatures from 170K (-100°C) to 550°C thanks to the use of two specific platens developed by IBS.

This delivery comforts the choice of IBS to offer a R&D line of equipment (IMC) for high-end research applications and a brand-new line (FLEXion) for production of emerging technologies.

As the first Chinese IMC-200 ion implanter is now in production at Xi’An Jiaotong University, IBS enters a market that represents more than 75% of the yearly worldwide sales of advanced semiconductor equipments. With already 80% of IBS business made overseas, this sale is the first step towards IBS goal to double its turnover within the next 4 years in terms of equipment sales.

As the result of a strong collaboration between IBS and CEA (French Atomic Energy research center), the first IBS PULSION® SOLAR PIII system is fully operational at INES (National Institute for Solar Energy) research facilities since January 2017.

The latest model of IBS PULSION® PIII systems, the PULSION® SOLAR implanter, addresses two main challenges of solar energy development: Cost of production for high yield photovoltaic cells, and improvement of their performances.

IBS announces a sale of its latest PULSION® HP tool 300mm immersion plasma tool.

The purchase order was from an undisclosed leading semiconductor company in the USA.

Moreover, IBS confirms the success of PULSION® Nano product line with the delivery of 3 new equipments.